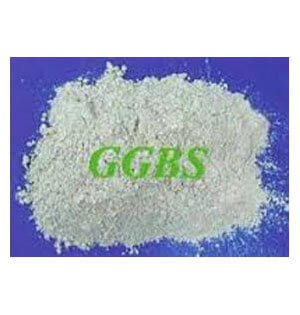

Granulated Blast Furnace Slag is obtained by rapidly chilling (quenching) the molten ash from the furnace with the help of water. During this process, the slag gets fragmented and transformed into amorphous granules (glass), meeting the requirement of IS 12089:1987 (manufacturing specification for granulated slag used in Portland Slag Cement). The granulated slag is ground to desired fineness for producing GGBS.

The multi-fold advantages of GGBS when used with Portland cement

- Ensures higher durability of structure.

- Reduces the temperature rise and helps to avoid early-age thermal cracking.

- Improved workability.

- It is off-white in colour and substantially lighter than Portland cement. Resultantly it helps soften the visual impact of large structures such as bridges and retaining walls.

Where GGBS can be used?

GGBS significant attribute of providing ultimate strength when added to Portland cement makes it the preferred material in the construction of;

- High-rise buildings.

- Marine applications such as dams, shore protection construction.

- Effluent and sewage treatment plants.

- Cement products such as tiles, pipes, blocks, etc.